Folding Carton

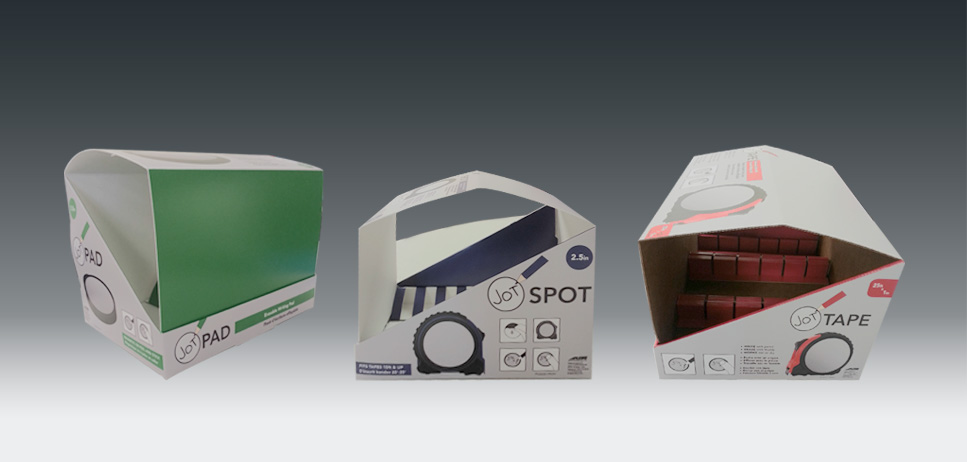

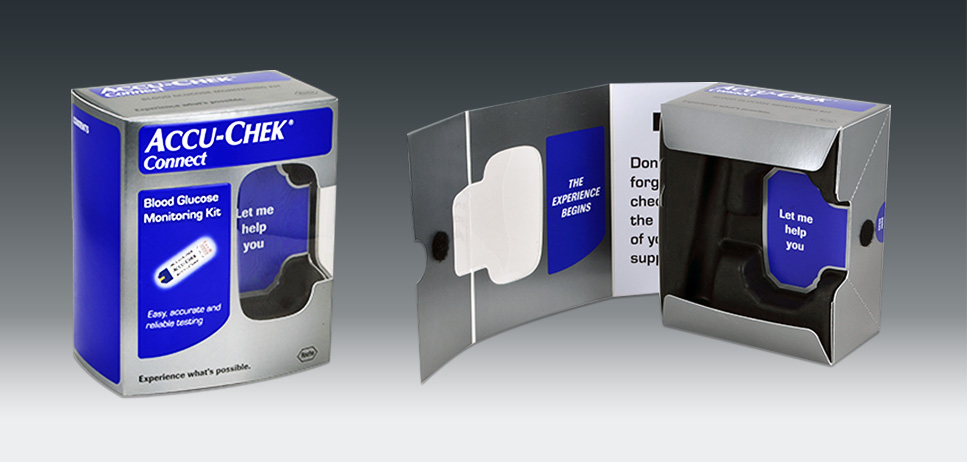

Folding cartons maximize the potential of your brand. Whether it’s a simple tuck end box or custom packaging, we can create the right folding carton for your unique product from concept to completion.

Folding cartons maximize the potential of your brand. Whether it’s a simple tuck end box or custom packaging, we can create the right folding carton for your unique product from concept to completion.

Dr. Brown's Boxes and Cartons[/caption]

Folding cartons can be made in many common styles, and quite a few custom styles. Some common styles are; Straight Tuck End Carton, Reverse Tuck End Carton, Tuck Tab Auto Bottom, Tuck Tab Snap Lock Bottom (or 1-2-3 Bottom), Full Overlap Seal End, Partial Overlap End Seal, Mailer Lock, Tuck Tab with Tongue, Edge Lock, Infold Bottom, Glued Simplex Tray, Infold Tray, Outfold Tray, Hinged Tray with Cover, Full Telescope, Partial Telescope, Slip Case and Tray Binder, Bellows Style Top and Bottom, Four Corner Beer Tray, Four Corner Beers with Tuck, Six Corner Beers, Stripper Lock Tray, Hinged Stripper Lock Tray, Pillow Pack, Frame View Tray, and Sleeve. Additionally cartons can have window openings, and windows with acetate glued in.

Corrugated boxes can be made in some of the same styles listed above, if the size of the box and the thickness of the corrugate is suitable. Usually however, corrugated boxes are utilized for larger boxes, or when more product protection is required. The fluted corrugated materials have a somewhat cushioning effect due to the multiple layers, with air space in between. Some corrugated box styles are Regular Slotted Container (RSC), Half Slotted Container (HSC), Full Overlap Slotted Container (FOL), Overlap Slotted Container, Central Special Slotted Container, Rolled End Lock Tray, Five Panel Folder, One Piece Folder, Stadium Tray, Integral Slotted Container, Tube, and Partition. Corrugated boxes can be printed either by Flexography (Flexo), Litho Label, Silk Screen, or Digital UV inks. Corrugated board comes in kraft (brown standard, and also in white on one side, or both sides. Specialty corrugated boards can be all white, black, or various combinations.

A last style of box to mention here is Rigid set up box. These boxes, while being the most expensive to produce, are made by wrapping a glued printed label over a thick chipboard, usually 40pt., 60pt., or 80pt. thick. This process is done by applying wet glue with a Potdevin machine, and hand wrapping in small quantities. Larger quantities can be wrapped by specialized machines.

Create It Packaging employs dieline creation, graphic design, printing, die cutting, and assembly of all listed box styles, point of purchase displays , floor displays, counter top displays, signage, and trade show graphics. Create It Packaging also designs and cuts custom box inserts, in either foam or board. We are a full service custom box manufacturer, not limited to small quantities. Our company specializes in one off, production quality, mock ups, samples, and prototypes. We typically produce sample runs in several days, and small production runs with quick turn around times, as well.

Dieline creation is the engineering process of creating box and carton dielines in a CAD program with specialized software. The structural designer takes into account the type and thickness of the stock to be used, to build in proper tolerances for folding and gluing. Decisions like crease scores vs. cut scores, friction locks vs. shore locks for tabs, glue assist areas, and many other considerations that are important to the box or cartons function. One of the structural designers main considerations is to how the box will be formed and glued in production. Without a proper structural design dieline, boxes and cartons risk the chance of many failures. Brian Lewis, owner of Create It Packaging, started in business as a structural designer about 25 years ago. Our company now has 2 designers on staff full time.

As custom box and carton designers and manufactures, final assembly of boxes, cartons, pouches, Point of Purchase displays, and wrappers, is the final construction. After dielines are created, graphics are flowed on, printing has taken place, and the die cutting is finished, gluing and assembly takes a prime role. Without skilled assembly, a quality finished product would not be possible. Our veteran staff of packaging assemblers are skilled is finishing packaging, from the simplest designs, to the most complex. An added benefit to our customers is in-house kitting and fulfillment. By employing a flexible size staff of trained temporary workers, we can throw as few or as many assemblers onto a project as necessary. Our costs are kept low due the temp force's low overhead, and they are ready at a day's notice. Currently our temp work force has been busy with pet products packaging, medical packaging, sports equipment fulfillment, and influencer kit pack outs. Perhaps we will be working on a product from your company, next?

A final word about Create It Packaging, is that we are the starting point for any type of packaging. Many packaging companies want to produce your long production run boxes and cartons, but are not very interested in getting you started. Whether you are a brand new company, or an established company launching a new product, or package, we are the company that is right for you. Packaging might have been the last thing you have thought about when beginning your product kick off, but now that you are here, please let us Create It!

Dr. Brown's Boxes and Cartons[/caption]

Folding cartons can be made in many common styles, and quite a few custom styles. Some common styles are; Straight Tuck End Carton, Reverse Tuck End Carton, Tuck Tab Auto Bottom, Tuck Tab Snap Lock Bottom (or 1-2-3 Bottom), Full Overlap Seal End, Partial Overlap End Seal, Mailer Lock, Tuck Tab with Tongue, Edge Lock, Infold Bottom, Glued Simplex Tray, Infold Tray, Outfold Tray, Hinged Tray with Cover, Full Telescope, Partial Telescope, Slip Case and Tray Binder, Bellows Style Top and Bottom, Four Corner Beer Tray, Four Corner Beers with Tuck, Six Corner Beers, Stripper Lock Tray, Hinged Stripper Lock Tray, Pillow Pack, Frame View Tray, and Sleeve. Additionally cartons can have window openings, and windows with acetate glued in.

Corrugated boxes can be made in some of the same styles listed above, if the size of the box and the thickness of the corrugate is suitable. Usually however, corrugated boxes are utilized for larger boxes, or when more product protection is required. The fluted corrugated materials have a somewhat cushioning effect due to the multiple layers, with air space in between. Some corrugated box styles are Regular Slotted Container (RSC), Half Slotted Container (HSC), Full Overlap Slotted Container (FOL), Overlap Slotted Container, Central Special Slotted Container, Rolled End Lock Tray, Five Panel Folder, One Piece Folder, Stadium Tray, Integral Slotted Container, Tube, and Partition. Corrugated boxes can be printed either by Flexography (Flexo), Litho Label, Silk Screen, or Digital UV inks. Corrugated board comes in kraft (brown standard, and also in white on one side, or both sides. Specialty corrugated boards can be all white, black, or various combinations.

A last style of box to mention here is Rigid set up box. These boxes, while being the most expensive to produce, are made by wrapping a glued printed label over a thick chipboard, usually 40pt., 60pt., or 80pt. thick. This process is done by applying wet glue with a Potdevin machine, and hand wrapping in small quantities. Larger quantities can be wrapped by specialized machines.

Create It Packaging employs dieline creation, graphic design, printing, die cutting, and assembly of all listed box styles, point of purchase displays , floor displays, counter top displays, signage, and trade show graphics. Create It Packaging also designs and cuts custom box inserts, in either foam or board. We are a full service custom box manufacturer, not limited to small quantities. Our company specializes in one off, production quality, mock ups, samples, and prototypes. We typically produce sample runs in several days, and small production runs with quick turn around times, as well.

Dieline creation is the engineering process of creating box and carton dielines in a CAD program with specialized software. The structural designer takes into account the type and thickness of the stock to be used, to build in proper tolerances for folding and gluing. Decisions like crease scores vs. cut scores, friction locks vs. shore locks for tabs, glue assist areas, and many other considerations that are important to the box or cartons function. One of the structural designers main considerations is to how the box will be formed and glued in production. Without a proper structural design dieline, boxes and cartons risk the chance of many failures. Brian Lewis, owner of Create It Packaging, started in business as a structural designer about 25 years ago. Our company now has 2 designers on staff full time.

As custom box and carton designers and manufactures, final assembly of boxes, cartons, pouches, Point of Purchase displays, and wrappers, is the final construction. After dielines are created, graphics are flowed on, printing has taken place, and the die cutting is finished, gluing and assembly takes a prime role. Without skilled assembly, a quality finished product would not be possible. Our veteran staff of packaging assemblers are skilled is finishing packaging, from the simplest designs, to the most complex. An added benefit to our customers is in-house kitting and fulfillment. By employing a flexible size staff of trained temporary workers, we can throw as few or as many assemblers onto a project as necessary. Our costs are kept low due the temp force's low overhead, and they are ready at a day's notice. Currently our temp work force has been busy with pet products packaging, medical packaging, sports equipment fulfillment, and influencer kit pack outs. Perhaps we will be working on a product from your company, next?

A final word about Create It Packaging, is that we are the starting point for any type of packaging. Many packaging companies want to produce your long production run boxes and cartons, but are not very interested in getting you started. Whether you are a brand new company, or an established company launching a new product, or package, we are the company that is right for you. Packaging might have been the last thing you have thought about when beginning your product kick off, but now that you are here, please let us Create It!